Fault diagnosis. II

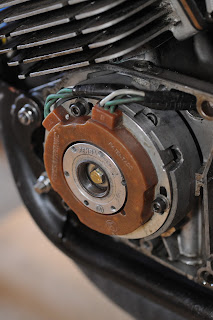

It couldn't be simple could it? Following on from Fault Diagnosis I (FD I), we have that other fault to figure out. I have left in the symptoms (in Italics ) that built up to this fault coming about as it paints the picture for how we went about investigating this fault. You should know the cause of FD I so try and find what caused the next snag. Symptoms The bike was on the dyno the day before having recently had a new ignition fitted and was running well with good power and safe temperatures. Engine started well on choke. In the waiting area for the Pembrey practice session; the bikes tick over was noticeably high with the right cylinder temperature climbing at a much higher rate to the left. Right pipe was running smokier than the left which would seem to balance somewhat when revved. During riding temperatures rose to near correct running temperature with left reading slightly lower at 138/149 max. Power delivery was very lumpy, bike seemed much happier w