Fault diagnosis. II

It couldn't be simple could it? Following on from Fault Diagnosis I (FD I), we have that other fault to figure out.

I have left in the symptoms (in Italics) that built up to this fault coming about as it paints the picture for how we went about investigating this fault. You should know the cause of FD I so try and find what caused the next snag.Symptoms

The bike was on the dyno the day before having recently had a new ignition fitted and was running well with good power and safe temperatures.

Engine started well on choke.

In the waiting area for the Pembrey practice session; the bikes tick over was noticeably high with the right cylinder temperature climbing at a much higher rate to the left.

Right pipe was running smokier than the left which would seem to balance somewhat when revved.

During riding temperatures rose to near correct running temperature with left reading slightly lower at 138/149 max.

Power delivery was very lumpy, bike seemed much happier wide open throttle.

Half way round lap 1, with temperatures close to operational, the bike entered the second hair pin.

The throttle was closed and gears dropped during deceleration.

Power loss was felt mid corner, on opening throttle the bike fired once or twice before bike was retired.

Investigation

- Changing tick over screws made no difference,

- Spark plugs were brown and slightly wet,

- Spark was crisp and blue,

- Fuel lines were unrestricted,

- Float chambers were getting fuel,

- carbs were fitted tightly,

- Air screws were at 1.5 turns out.

- Jetting was unchanged,

- Slack could be felt in the throttle,

- Throttle Slide balance was out by 1mm,

- Cable adjusters and carb tops were taped,

- No air restriction, carbs open,

- No exhaust restriction some leaks present.

Unsatisfied that FD I did not cause the bike to stop in this manner we continued investigation.

- Engine has good compression,

- Transmission and gearbox servicable,

- bike would fire intermittently whilst bump starting,

- No loose connections/damage to wiring,

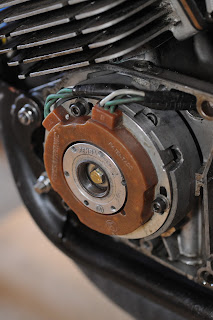

- No outward damage to rotor or stator,

- Ignition timing retarded 5.7 degrees BTDC.

Fault Cause

Due to the design of the ignition I was running, it does not use the woodruff key. As my crank tapered end was worn, the rotor had slipped which had pushed my timing out too far.

With both cylinders going down, it was more likely a common problem was occurring. With air or fuel starvation removed as a factor this left ignition.

A clean up of the crank taper helped but other options are being investigated to prevent this happening again such as running the ignition 180 degrees out in order to use a woodruff key.

Comments

Post a Comment